Dimensions of a Coping Saw

Coping saw sizes especially their blades, differ,  with some blades 6 ½ niches long. You will also see some coping saws that have 7 in long blades. Heavy duty saw will have much longer and larger blades.

with some blades 6 ½ niches long. You will also see some coping saws that have 7 in long blades. Heavy duty saw will have much longer and larger blades.

Basic Facts

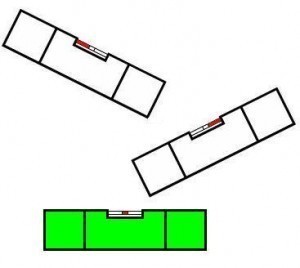

The coping saw is a handsaw designed for cutting different kinds of shapes and curves. The name is derived from the coped joint. The saw is constructed using a tension frame shaped like a U or C. On one side of the frame is a handle. The blade of the saw is connected to a side of the frame.

The saw blade is strung by the frame opening. The teeth will be oriented towards the handle. Whatever the coping saw size is, adjustments to the tension can be made. Adjustments are done using the coping saw screws or the wing nuts.

By making the proper adjustments, it will be easy to attain precise control levels. These adjustments are usually done by people who have attained some skills in using coping saws.

How to Use the Coping Saw

First you must decide what molding piece will be against the wall corner. Those with the longest run are usually the best choices. Now you have to cut the end so it fits the wall correctly. You can nail the molding to secure it.

Now position the miter at a 45 degree angle. Set the second molding piece on the box. Cut it with the saw. The molding end can be cut by the coping saw. Make the cut from the mitered end down. Place the molding at the end of the tacked molding.

Tips

Try cutting different kinds of molding. In some molding it will be necessary to keep the top edge and slice the rest off. It’s important to keep practicing, as coped joints are complex.

Other Uses of the Coping Saw

Besides coped joints, these can be used for making cutouts, adding curved edges to wood and other intricate designs. Just like other tools, the efficiency of the coping saw depends on how well it is taken care of. The blade must be cleaned after being used each time. Oiling will also keep it from getting rusty.

Whatever coping saw size you use, always wear gloves and safety glasses. You should also replace the blades if they are dull. Working with dull blades will produce uneven cuts and may even chip the material.